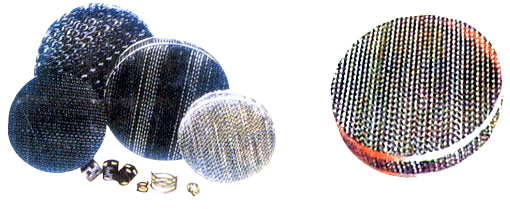

[Packed of Column]

Under the direction of Shanghai Research Institute of Chemical Industry, we professionally manufacture High-efficient Structured Packing Column and Random Packing in stainless steel, bronze, aluminum, pure titanium, molybdenum titanium and other materials to widely apply in spice, pesticide, fine chemistry and petro-chemistry. Structured packing column can be classified as mesh, screen, orifice plate, rolled orifice plate and other types. Random packing mainly has metal Pall ring packing, metal cascade ring packing and metal saddle ring, i.e., Intalox packing. |

|

| Geometric parameter of SW type mesh packed of column |

|

Packing Model

|

Material

|

h mm

Peak

|

m2/m2

Specific Surface Area

|

ah/mm

Hydraulic Diameter

|

Oblique Angle |

%

Porosity

|

m/s kg/m2

f factor

|

no/m

Theoretical Number of Plate

|

mmhg/m

Pressure-drop

|

| SW-1Type |

Stainless Steel |

4.5 |

643 |

5.7 |

45 |

91.6 |

1.4-2.2 |

5-8 |

2-3.5 |

| SW-1Type |

6.5 |

450 |

9 |

30 |

95.5 |

1.5 |

4-5 |

1.6-1.8 |

|

| Geometric parameter of screen packed of column SC=CY SB=BX |

|

Packing Model

|

Material

|

h mm

Peak

|

m2/m2

Specific Surface Area

|

ah/mm

Hydraulic Diameter

|

Oblique Angle |

%

Porosity

|

m/s kg/m2

f factor

|

no/m

Theoretical Number of Plate

|

mmhg/m

Pressure-drop

|

| CY |

Stainless Steel |

4.3 |

700 |

5 |

45 |

87-90 |

1.3-2.4 |

6-9 |

5 |

| BX |

6.3 |

500 |

7.3 |

30 |

95 |

2-2.4 |

4-5 |

1.5 |

|

| Geometric parameter of orifice plate |

|

Packing Model

|

Material

|

h mm

Peak

|

m2/m2

Specific Surface Area

|

ah/mm

Hydraulic Diameter

|

Oblique Angle |

%

Porosity

|

m/s kg/m2

f factor

|

no/m

Theoretical Number of Plate

|

mmhg/m

Pressure-drop

|

| SM125 |

Stainless Steel |

24 |

125 |

35 |

45 |

98.5 |

3 |

1-1.2 |

1.5 |

| SM225 |

12 |

250 |

15.8 |

45 |

97 |

2.6 |

2-3 |

1.5-2 |

| SM325 |

8 |

350 |

12 |

45 |

95 |

2 |

3.5-4 |

1.5 |

| SM425 |

6.5 |

450 |

9 |

45 |

93 |

1.5 |

3-1 |

1.8 |

|

| Geometric parameter of rolled orifice plate packed of column |

| Packing Model |

Material

|

h mm

Peak |

m2/m2

Specific Surface Area

|

ah/mm

Hydraulic Diameter

|

Oblique Angle |

%

Porosity

|

m/s kg/m2

f factor

|

| 700Y |

Stainless Steel |

5-7 |

4.3 |

85 |

700 |

7 |

1.6 |

| 500X |

3-4 |

6.3 |

90 |

500 |

2 |

2.1 |

| 250Y |

2.5-3 |

|

97 |

250 |

2.25 |

2.6 |

|

|

|