|

Summarization:

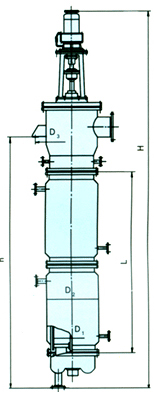

the device is a high-efficient evaporator and distillator to make liquid into even film for evaporation or distillation  through high-speed rotation. It can also carry out deodorizating and defoaming reaction as well as equip with heating and cooling operation to be widely applied in Chinese and western medicine, foods, light industry, petroleum, chemistry, environmental protection and other industries. through high-speed rotation. It can also carry out deodorizating and defoaming reaction as well as equip with heating and cooling operation to be widely applied in Chinese and western medicine, foods, light industry, petroleum, chemistry, environmental protection and other industries.

The evaporator adopts internationally advanced technology to take the leading role in domestic film evaporator field. The device used to be the core part of vacuum scraping mixer set and gain the third place of technological progress award issued by State Drug Administration.

Performances and Features

Adopting centrifugal sliding groove rotor, the device is the evaporator with latest structure in foreign country, which can form film even in tiny flux. The deposition attached on the surface of inner wall of evaporating cylinder can be scraped immediately. Comparing to scraping evaporator with fixed interval, the evaporating volume can increase 40 to 69%. It obtains the following performances and features:

Heat conduct factor is high and evaporation is large to be 200kg/m2·hr, thus, thermal efficiency is high.

Time to heat material is short, around 5 to 10 seconds. It operates in vacuum, which is more suitable for thermal material, to prevent any ingredient decompositions and ensure product quality.??

Wide availability to viscosity changes allows dealing with materials in high and low viscosity, up to 100 thousand CP.

Changing scraping groove can adjust processing duration of material in evaporator.

Inner wall of evaporating cylinder is precisely bored and polished to avoid coking and dirt on surface.

Easy operation and adjustment of product code can ensure continuous automatic manufacture in sealed condition.

Device takes up small room to have the features of simple structure, convenient maintenance and easy cleaning.

|